概要 / Overview

本研究室ではこれまで知られていなかった自然界や生物の運動時に働く力学に対して、それぞれの対象に特化したMEMSの力センサを開発し計測を行うことで、その解明に取り組んでいます。さらに研究によって得られた知見を生かし、社会に直接役立つMEMSのデバイスとして還元していくことを目指しています。

具体的には以下に代表されるような研究を行っています。

In our laboratory, against unknown mechanics of animal locomotion and nature phenomena, we try to clarify them by developing MEMS force sensors specialized for each target. Moreover, we would also like to give our research knowledge back to society as new industrial MEMS products.

Current working projects include:

MEMS力センサによる足裏反力 / Ground reaction forces using MEMS sensors

Terrestrial insects such as ants are known for their agile locomotion on six legs. In this report, a micro force plate array is presented that uses the Sampling Moiré (SM) method, a prism, and a single camera to simultaneously measure the triaxial GRFs of multiple legs of an ant during its locomotion. The proposed micro force plate array consists of a 3 × 3 array of 2900 × 2900 × 70 µm plate bases with a gap of 100 µm as the contact surface of the ant legs. The plate base is supported by a spring structure with a grid pattern. By capturing this grid pattern from the backside via a prism, a camera can capture images from two different directions, allowing the triaxial displacement to be measured. By dividing the plate surface into nine sections and evaluating the error based on the position of the force application in the z-direction force, a maximum measurement error of 6% was found. The average force resolution in the x, y, and z directions for the 9 plates were 3.34, 2.47, and 1.20 µN, respectively. With the developed force plate array, it was possible to measure the GRF of each leg simultaneously while the ant was walking.

Terrestrial insects such as ants are known for their agile locomotion on six legs. In this report, a micro force plate array is presented that uses the Sampling Moiré (SM) method, a prism, and a single camera to simultaneously measure the triaxial GRFs of multiple legs of an ant during its locomotion. The proposed micro force plate array consists of a 3 × 3 array of 2900 × 2900 × 70 µm plate bases with a gap of 100 µm as the contact surface of the ant legs. The plate base is supported by a spring structure with a grid pattern. By capturing this grid pattern from the backside via a prism, a camera can capture images from two different directions, allowing the triaxial displacement to be measured. By dividing the plate surface into nine sections and evaluating the error based on the position of the force application in the z-direction force, a maximum measurement error of 6% was found. The average force resolution in the x, y, and z directions for the 9 plates were 3.34, 2.47, and 1.20 µN, respectively. With the developed force plate array, it was possible to measure the GRF of each leg simultaneously while the ant was walking.

[Ref] T. Shiratori and H. Takahashi, IEEE Sensors Journal, 2025.

[Ref] N. Ono et.al., IEEE Sensors Journal, 2025.

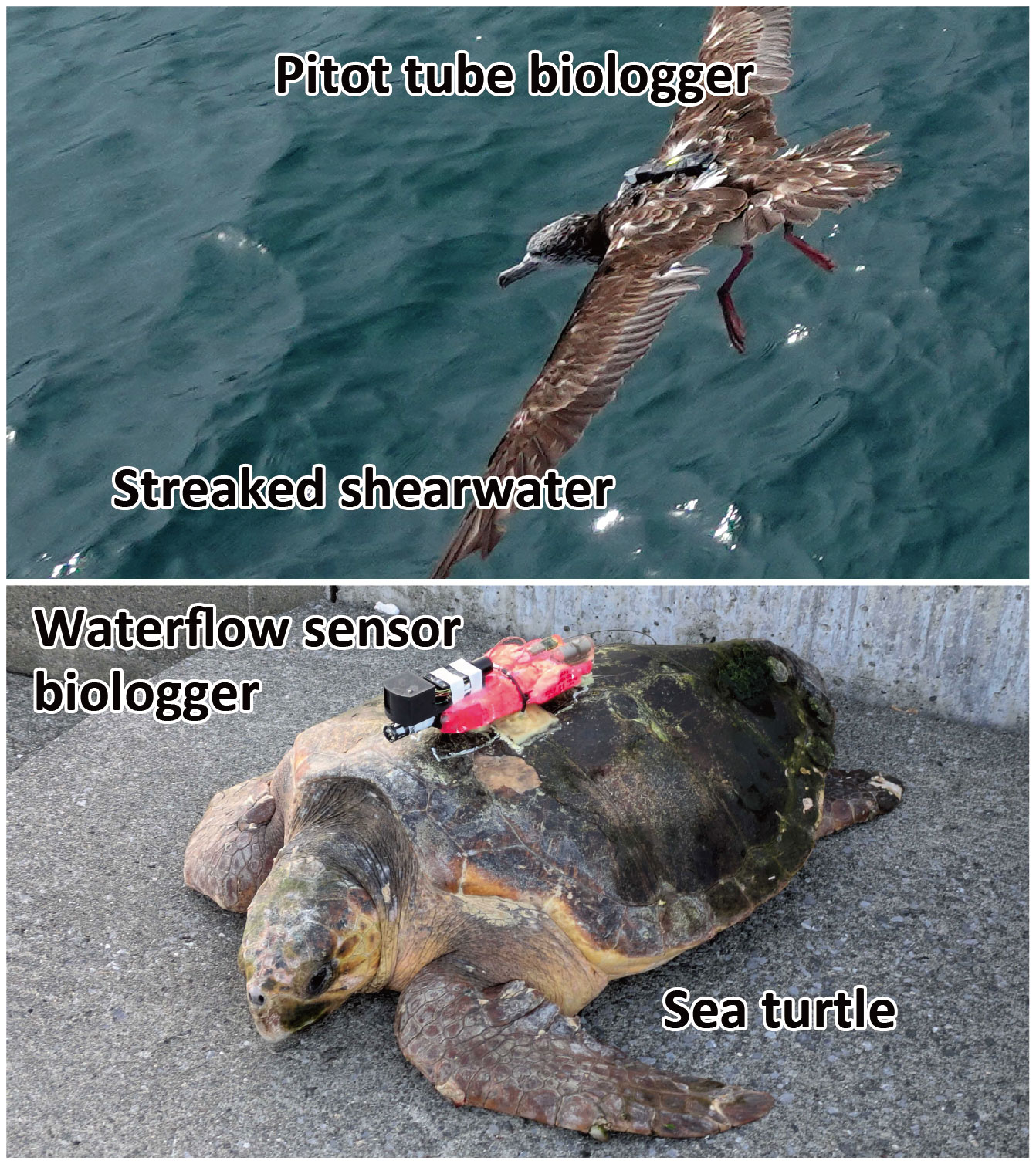

バイオロギングのためのセンサ開発 / Sensor development for biologging

Here we present an airflow sensor for seabird biologging. To attach the sensor to the biologging system, the sensor must be waterproof because seabirds dive into the seato prey on fish. In addition, the sensor must also be compact and have high sensitivity. Here, we propose a Pitot tube-type airflow sensor that satisfies these requirements. The proposed sensor is composed of MEMS piezoresistive cantilevers as sensing elements with high sensitivity and anodic alumina membranes with a nano-hole array as the waterproof elements with airflow penetration. The developed sensor responded sufficiently to airflow velocities from 2 m/s to 20 m/s. Inaddition, the sensor maintained its sensitivity after plunging into the water and returning to the air. Therefore, the proposed sensor can be utilized for practical seabird biologging.

Here we present an airflow sensor for seabird biologging. To attach the sensor to the biologging system, the sensor must be waterproof because seabirds dive into the seato prey on fish. In addition, the sensor must also be compact and have high sensitivity. Here, we propose a Pitot tube-type airflow sensor that satisfies these requirements. The proposed sensor is composed of MEMS piezoresistive cantilevers as sensing elements with high sensitivity and anodic alumina membranes with a nano-hole array as the waterproof elements with airflow penetration. The developed sensor responded sufficiently to airflow velocities from 2 m/s to 20 m/s. Inaddition, the sensor maintained its sensitivity after plunging into the water and returning to the air. Therefore, the proposed sensor can be utilized for practical seabird biologging.

[Ref] T. Kishimoto et.al., IEEE Sensors Journal, 2015.

[Ref] T. Kishimoto et.al., IEEE Sensors Journal, 2021.

高感度MEMS力センサの工学応用 / New application of MEMS force sensors

This study proposes a compact sphere airflow vector sensor using a neural network model that compensates for nonmonotonicity. It consists of three built-in microelectromechanical system (MEMS)-based DP sensor elements that simultaneously measure the DPs around the spherical sensor housing. The measured DPs are converted into 2D wind speed and direction using a neural network. The network model was trained using the simulated output of each sensor, and it was confirmed that the proposed design guideline contributed to achieving high accuracy. An airflow sensor was fabricated on the basis of the designed model. A network model was trained using the sensor responses in a wind tunnel experiment. The wind speed and direction accuracies obtained by the neural network model for 2–10 m/s and 0◦–359◦ were 0.24 m/s and 3.62◦, respectively. Finally, we demonstrated a drone flight test by attaching the calibrated sensor to a toy drone. This study is expected to contribute to realizing highly accurate low airflow measurement devices.

This study proposes a compact sphere airflow vector sensor using a neural network model that compensates for nonmonotonicity. It consists of three built-in microelectromechanical system (MEMS)-based DP sensor elements that simultaneously measure the DPs around the spherical sensor housing. The measured DPs are converted into 2D wind speed and direction using a neural network. The network model was trained using the simulated output of each sensor, and it was confirmed that the proposed design guideline contributed to achieving high accuracy. An airflow sensor was fabricated on the basis of the designed model. A network model was trained using the sensor responses in a wind tunnel experiment. The wind speed and direction accuracies obtained by the neural network model for 2–10 m/s and 0◦–359◦ were 0.24 m/s and 3.62◦, respectively. Finally, we demonstrated a drone flight test by attaching the calibrated sensor to a toy drone. This study is expected to contribute to realizing highly accurate low airflow measurement devices.

[Ref] T. Kato and H. Takahashi, Jpn. J. Appl. Phys., 2025.

[Ref] K. Shimada et.al., Jpn. J. Appl. Phys., 2025.

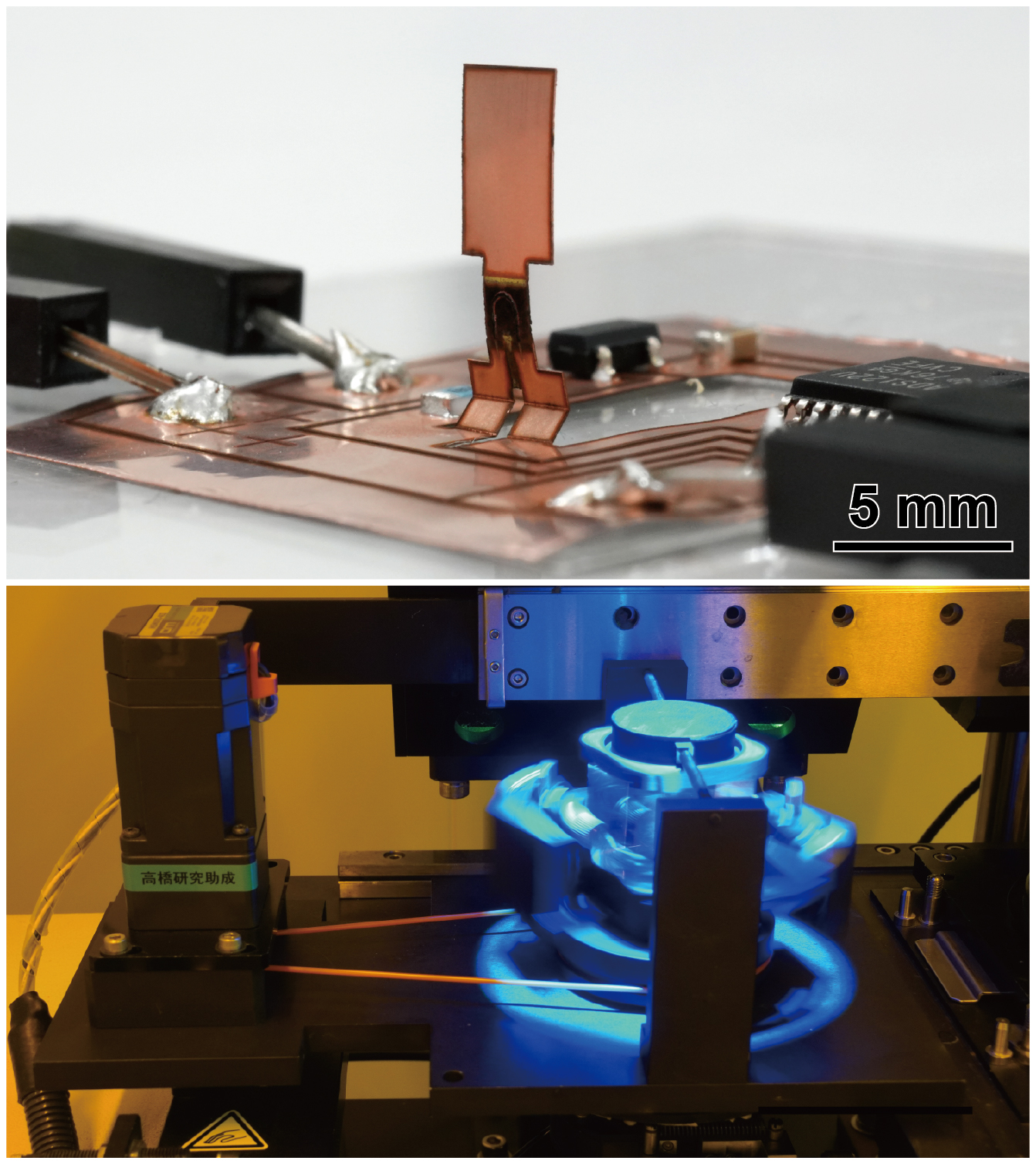

新しいMEMSプロセスの構築 / Development of MEMS fabrication process

MEMS sensors based on piezoresistive elements are widely used in various applications due to their high sensitivity and compact size. Traditionally, silicon‐based MEMS devices have been fabricated using lithography‐based processes, with piezoresistive layers formed through thermal diffusion or ion implantation. In response, laser fabrication techniques, such as laser micromachining and laser annealing‐based impurity diffusion, have attracted attention. In this study, a laser‐based approach for fabricating a silicon piezoresistive cantilever using nanosecond‐pulse laser annealing is proposed. The proposed process integrates two steps: localized laser annealing for impurity doping and the formation of a partially 3D cantilever structure through laser cutting and etching. All the fabrication steps are performed using a single‐laser processing system, enabling direct‐write patterning and automatic alignment of the piezoresistive layer with the sensor structure without lithography. In this paper, the effectiveness of the proposed method is evaluated through electrical and mechanical characterizations of the fabricated sensor.

MEMS sensors based on piezoresistive elements are widely used in various applications due to their high sensitivity and compact size. Traditionally, silicon‐based MEMS devices have been fabricated using lithography‐based processes, with piezoresistive layers formed through thermal diffusion or ion implantation. In response, laser fabrication techniques, such as laser micromachining and laser annealing‐based impurity diffusion, have attracted attention. In this study, a laser‐based approach for fabricating a silicon piezoresistive cantilever using nanosecond‐pulse laser annealing is proposed. The proposed process integrates two steps: localized laser annealing for impurity doping and the formation of a partially 3D cantilever structure through laser cutting and etching. All the fabrication steps are performed using a single‐laser processing system, enabling direct‐write patterning and automatic alignment of the piezoresistive layer with the sensor structure without lithography. In this paper, the effectiveness of the proposed method is evaluated through electrical and mechanical characterizations of the fabricated sensor.

[Ref] K. Ohara et al, Advanced Sensor Research, 2025.

[Ref] R. Nakashima et.al., Advanced Sensor Research, 2025.

![]() This work was supported by JKA and its promotion funds from KEIRIN RACE (2023).

This work was supported by JKA and its promotion funds from KEIRIN RACE (2023).